IP COURT CASE SUMMARY “PLAITIFF FAILED TO SHOW THAT ACCUSED DEVICE PERFORMES A CLAIMED FUNCTION”-H20(Wa)12409

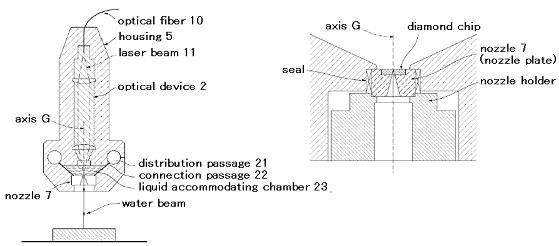

The patent related to a method and apparatus for laser machining. The apparatus has a laser 1 for generating laser beam 3. Laser beam 3 is transmitted through focus lens 5, beam guide 6, collimator lens 21, and focal lens 25 and focused as indicated at 56 into a liquid beam 12 flowing toward a material to be machined. As best shown in Fig. 3, the apparatus has a nozzle (nozzle plate) 43 and a transparent plate 36 mounted above nozzle 43 to define a liquid chamber 35 between them. Nozzle plate 43 has an inversely tapered nozzle 23 with a top inlet opening 30. The invention is featured in that the liquid flows within chamber 35 radially toward inlet opening 30 without being blocked around inlet opening 30 so that a liquid flow rate within a focusing cone region 56 is sufficiently high to prevent a formation of thermal lens which would damage the nozzle wall.

Independent claims 1 and 5 have a functional language “liquid is guided to flow radially toward the nozzle inlet opening 30 within the disk-like liquid supply chamber 35 setting a height of the window 36 from the nozzle plate 43 so that no blocking space exists around the nozzle inlet opening 30 and thereby a flow rate of the liquid in a focusing-cone tip region 56 of the laser beam is determined sufficiently high, so that a generation of thermal lens is prevented to the extent that a part of the laser beam does not damage a nozzle wall within the focusing-cone tip region 56”.

The defendant argued that the accused device shown below uses a green laser having a wavelength of 532 nm of which absorptivity to water is significantly low, so that no thermal lens to the extent capable of damaging the nozzle wall would occur in the accused laser device. To counter this argument, the plaintiff conducted two experiments and showed that, even using green laser, the thermal lens capable of damaging the nozzle wall within the liquid supply region could be formed.

The court noted in the decision that, in order to show that the accused method using the accused device performs the claim limitations in question, the plaintiff must show that

(1) no damage occurred in the nozzle wall of the accused device; and

(2) this result was derived from the fact that a flow rate of the liquid in a focusing-cone tip region of the laser beam was determined sufficiently high, so that a generation of thermal lens was prevented to the extent that a part of the laser beam did not damage a nozzle wall within the focusing-cone tip region,

but the plaintiff failed to show those facts.